Function

Pressure is an important machine of production line,use for pressure al-foil container.

Product Features

High performance frequency control, so that energy saving and environmental protection

High performance air operated clutch, low noise and longlife work.

High abrasion proof air pressure balance cylinder, so that pressing noise is low.

High speed signal pickup coder, so controling is much easier.

Auto-photoelectricity protection system, make it more safety.

Multipass air storage system, can cotrol air consumption reasonably.

Auto-lubrication system.

Moter driven adjust die set height

Technical Data

| Rated pressure | Punch time | Stroke | Maximum die set height | Die set height adjustment | Distance from Slider’s center to body | |

| 80kN | 20-70 times/minute | 300mm | 520mm | 80mm | 510mm | |

| work table size | Board hole size of work table | thickness of work table | Slider’s size | Machine power | Net weight | size |

| 680×680mm | 130mm | 420×620mm | 13kw | 13000Kg | 2500×1600×3600mm(L×W×H) | |

Please Affirm The Following Work Before Work.

1.Load curve: The press isn’t fit for compressing and squeeze forming. The max working force should be less than nominal force.

2.Torque capacity is determined with the slide block position. The sum of the technological force should be within pressure curve area.

3.In order to prevent the friction surface of clutch and brake against heat or getting failure, the max, permission strokes on single mode should be 30 min-1

Configure And Technical Specification

| configure | type | HHYLJ21-40 |

| Welding frame with steel plate | ● | |

| Motor | normal motor | ● |

| magnetic Speed-adjustable motor | ||

| Clutch | Dry air clutch | ● |

| Wet air clutch | ||

| overload protector | Shearing protector | ● |

| Hydraulic protector | ||

| Dual valve | Domestic valve | ● |

| Importing valve | ||

| Manual mould height adjustment | ● | |

| Output shaft of power | ||

| Lubrication mode | Motorized grease | |

| Handle grease | ● | |

| Electric control | PLC controller | ● Mitsubishi |

| Importing switch type cam controller | ||

| Homemade switch type | ● | |

| optional | 1. Change to a speed regulating motor | ○ |

| Option | 2. speed-adjustable motor | |

| 3. Output shaft of power | ○ | |

| 4. Importing dual valve | ○ | |

| 5. Motorized grease | ○ | |

| 6. Importing switch type controller | ○ | |

| 7. Air cushion | ○ | |

| 8. Blowing equipment | ○ | |

| 9. Photoelectric device | ○ | |

| Note: In this manual, ● indicates conventional configuration; ○ indicates optional configuration | ||

Work Principle And Structure Characteristics

The press adopts the crank and pitman mechanism, to make slide block moves up and down in frame guideways and do punching work. The press adopts the vertical crankshaft structure and fixed bed type. The frame is welded with steel plate and has high rigidity. Driving system is installed into the frame, so the structure is compact and the contour is beautiful. Speedy gear is immersed in oil tank, the transmission is smooth and the noise is low. Using the combined pneumatic friction clutch and brake, the press is easy to install and maintain. The slide block is foundry box which is installed a overload protector. When the press is overload. It can protect the machine

and die set against damaging. The die set height is adjusted by motor and is indicated by a digital indicator of 0.1mm precision. The weight of slide block is balanced by air balance cylinders, meanwhile slide block runs along six-face rectangular guide ways to improve its moving precision.

Electric equipment is controlled by PLC to improve operating reliability. Main motor has right and left direction function. Double valves can assure safe operation. Both hands buttons and optional photoelectrical device is to protect safety of operator. Besides, with the power shaft, the press can equip with automatic feeder, uncoiler and leveler device to form automatic production line.

Construction And Adjustment Of Main Assemblies

Frame of the press is a whole structure welding with steel plate. There sets copper bushes on the front and back neck of the crankshaft. Gear is set into the shut oil tank.

There is a cover plate onto the press where we can fill up oil and make gear shaft immersed within oil. The oil height is determined by oil leveler on the left side of the press. There set an outlet on the bottom of the oil tank to replace oil.

Two bearing plates at the back of the frame is used to fix motor. Guide track of frame is six-face rectangle which can be adjusted is fore and aft, left and right direction. We can adjust the clearance of fore-and-aft direction properly by adjusting pads, then screw the front bolts firmly. The clearance of left and right direction can be adjusted by adjusting six group bolts. Firstly loosen the packing bolts in front of the frame, then adjust the bolts on both sides, after that, lock the bolts and screw the packing bolts firmly.

There set an ejector in front of guide tracks. Adjust knock-out bolts to have the ejector function just at the position when the slide block reaches its top dead point. Pay attention to avoiding the touchment of ejector and the bottom of knock-out groove so as to prevent accidents.

Driving system

The drive system is driven by motor through V-belts and pneumatic clutch, then through gear shaft, big gear, the crank and pitman mechanism to make slide block run up and down.

The motor is tightened on bearing plate through rubber cushion. You can adjust four adjustable bolts and tighten nuts so as not to cause accidents.

Driving gear adopts immersed lubrication. There set angle indicator in front of crankshaft. A chain wheel is set at the back of crankshaft, which transmits the movement of crankshaft to cam controller so that the controller can send various signal to control the press.

Electric Parameters

| Electric | Brand name |

| Plc | Siemens |

| Inverter | Siemens |

| Solenoid valve | AirTAC |

| Switching power | Delta |

| Driver | Delta |

| Display | Delta |

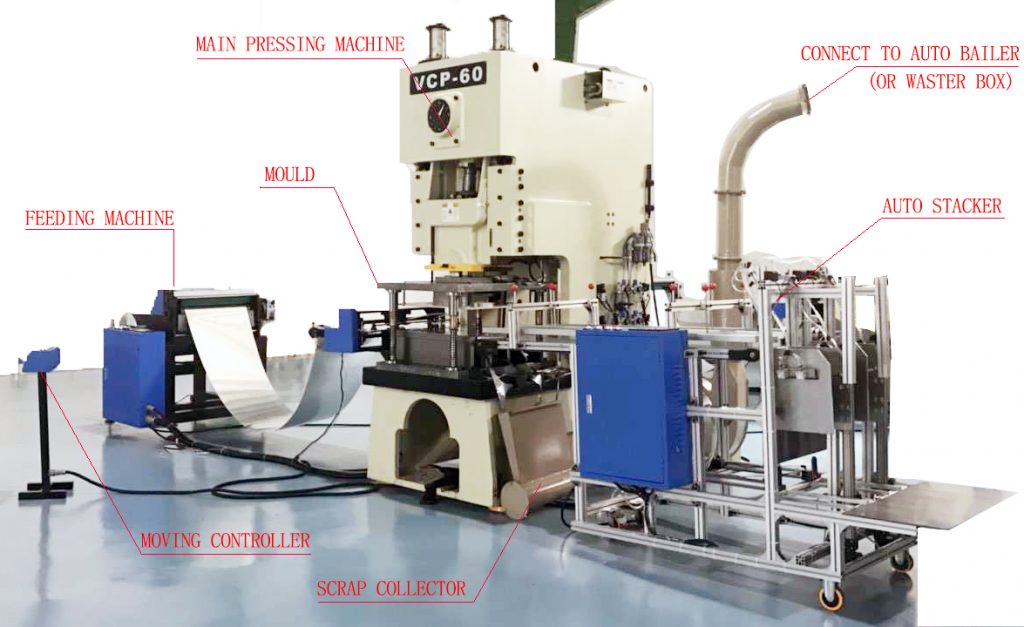

The NK-63 production line consists of NK-F800 feeder, NK-P63 high-precision press, NK-AS800 automatic stacker, and NK-SC500 waste edge collector. Compared with the NK-AT45 production line, a complete set of mechanical equipment with better performance, larger size and higher power is used, which makes up for the shortcoming that NK-AT45 cannot produce some large-sized special lunch boxes. If you want to produce most boxes in the market, then the NK-AT63 production line is your best choice. For entrepreneurs with certain economic strength, the NK-AT63 production line is the best solution in one step.

On the basis of MT45, CSD-AT45 adds automatic stacker and waste edge recycling system, which greatly improves production efficiency. One worker can complete production line inspection, product quality inspection, packaging and sealing at the same time, saving labor, The production cost is greatly reduced. The production line consists of a feeder, a precision press, an automatic stacker, and a waste edge recycling machine. (You can choose the mold according to your needs)

Product performance characteristics

1. The whole machine adopts programmable controller as the control system, which is safe and reliable. The parameters such as feeding length and production speed are simple to set, gas-electric integration, centralized control, and fully automatic production.

2. Feeding, punching and product ejection during operation are all automated.

3. The precision press adopts steel plate welded body, variable frequency speed regulation, dry friction clutch, rigid overload safety device, and has the characteristics of high precision and good reliability.

4. The feeding system adopts step control, and the feeding length is accurate and error-free, and can be set arbitrarily within the length range of 20mm-999mm.

5. The stacker is controlled by touch screen and PLC computer, and the lifting table adopts stepping and ball screw platform. It has the anti-collision function of the lunch box table, and the automatic counting function can be linked with the production line or used alone.