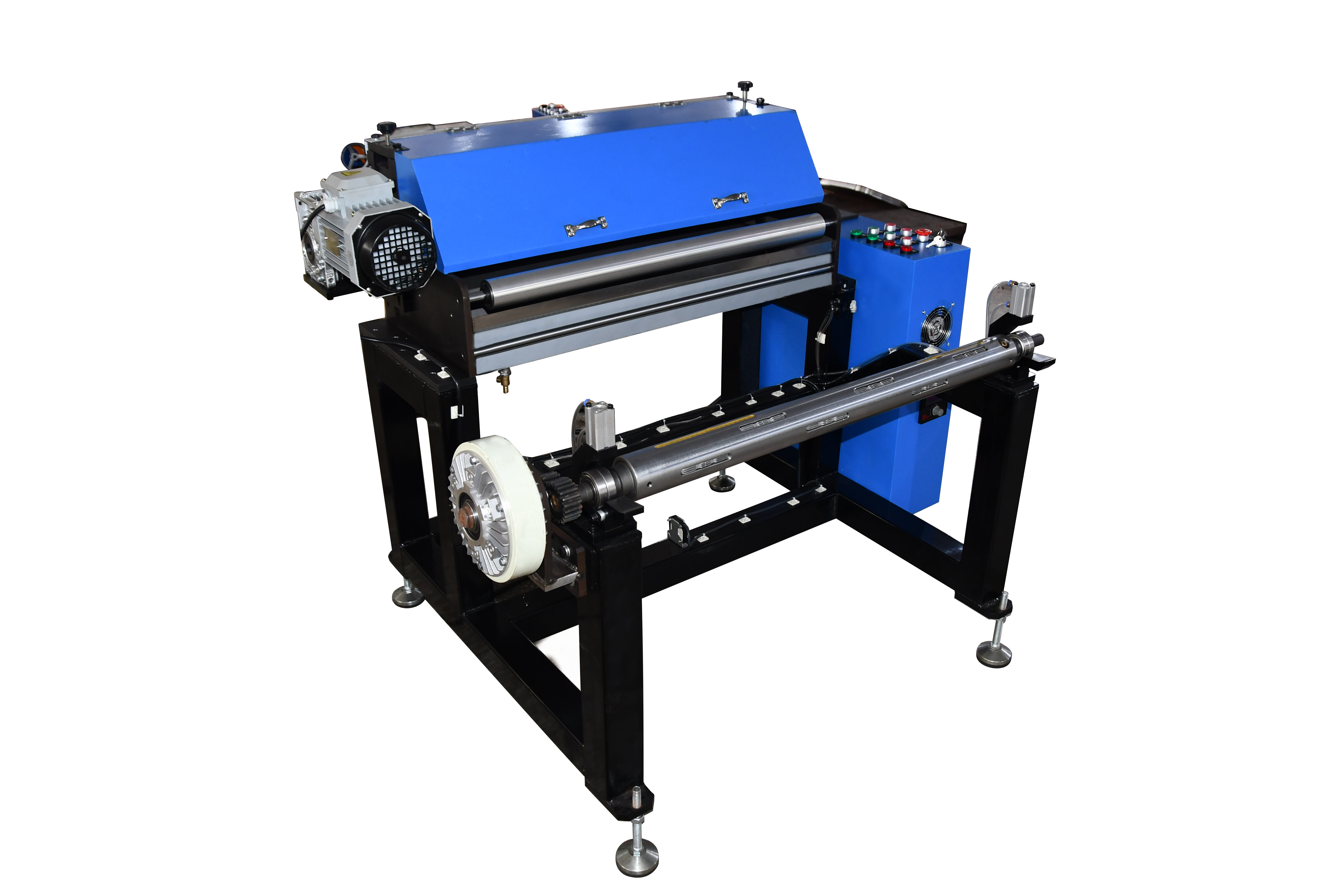

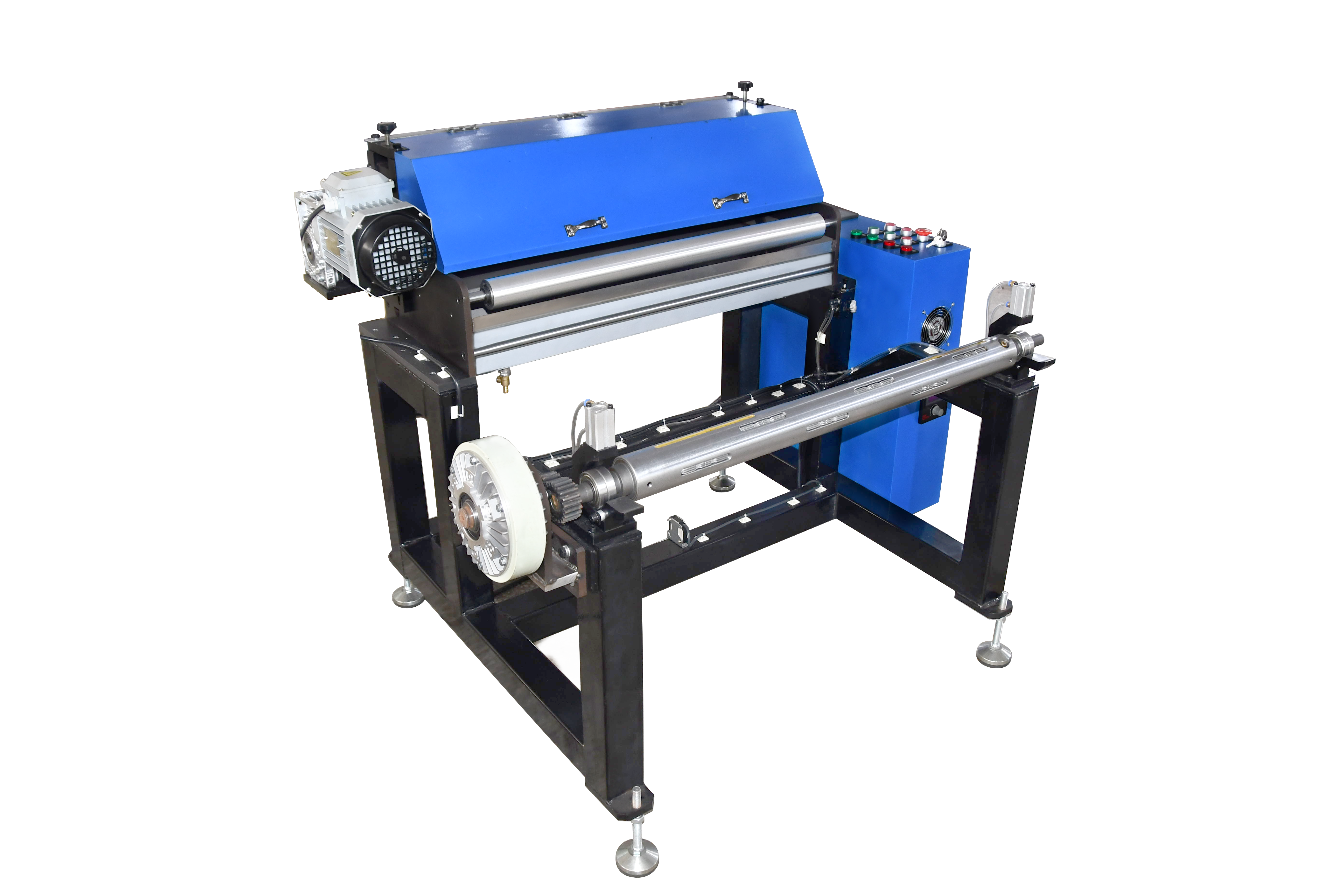

Function

Hydraulic pressure feeder is a important part of production line,is used for punch raw material and setlength and feeding automatically,also have uprush and press gas,disinfection automatically,wash products and embossing.lt can adjust pressure’s speed,inching/continue,air blast angle and auto-lubrication.

Product Features

Auto-Hydraulic feeding faction(select by favorites)

Obuturatorspindle and feeding by air operated

Double magnetic powder tension control system to make the tension control more smooth

Punching oil auto-recirculating system,is good for series of alu-foil container’s production,and save gas.

Closed fuel tank,layout resonable

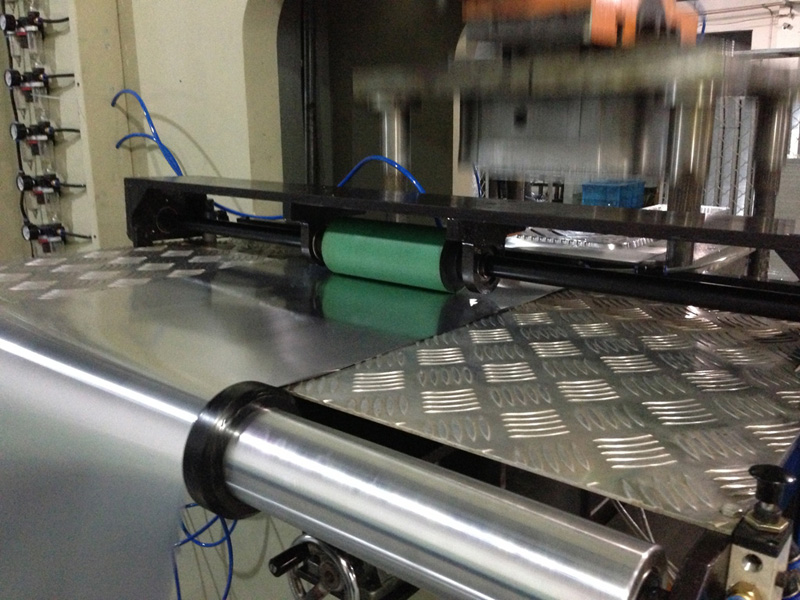

Using high wear-resisting of silicon roller,so that the machine can work longlife.

complete machine linkage,adopt touchscreen and PLC computer control, accuracy higher

Portable type command Control consol,so that operation is much easier and more convenience

Simplified styl tracking system, good for prodution

Feeder Parameters

| ModelSpecification | CSD-F600 | CSD-F800 | CSD-F900 |

| Lifting stroke | 250mm | 250mm | 250mm |

| front and rear stroke | 250mm | 250mm | 250mm |

| Max roll diameter | ø1000mm | ø1000mm | ø1000mm |

| Max width of the material | 600mm | 800mm | 900mm |

| Feeding length | 0.1~9999mm | 0.1~9999mm | 0.1~9999mm |

| Feeding accuracy | ±0.1mm | ±0.1mm | ±0.1mm |

| Feeding speed | 1-60m/min | 1-60m/min | 1-60m/min |

| Power | 2.5kw | 2.5kw | 2.5kw |

| Max rack weight | 1300KG | 2000KG | 2500KG |

| Feed roller diameter | ø100 | ø100 | ø100 |

| Feed roller material | Polyurethane、45# steel | Polyurethane、45# steel | Polyurethane、45# steel |

| Tractio roller diametern | ø102 | ø102 | ø102 |

| Tractio roller material | Polyurethane、45# steel | Polyurethane、45# steel | Polyurethane、45# steel |

| Rack Material | Q235 | Q235 | Q235 |

| Material of guide roller | Aluminum | Aluminum | Aluminum |

| Oil tank material | Stainless steel | Stainless steel | Stainless steel |

| Total Weight | 550kg | 600kg | 650kg |

| Size(L*H*W) | 1400mm*1300mm*1100mm | 1550mm*1300mm*1100mm | 1650mm*1300mm*1100mm |

Electric Parameters

| Electric | Brand name |

| Plc | Siemens |

| Inverter | Siemens |

| Solenoid valve | AirTAC |

| Switching power | Delta |

| Driver | Delta |

| Display | Delta |

OUR SERVICE:

1.quick response in before sales period help you got order.

2.excellent service in production time let you know each step we made.

3.reliable quality solve you after sale headache.

4.long period quality warranty ensure you can buy without hesitate.

Quality Assurance:

1. Strict control on choose of the raw material sources.

2. Speciific technology guide for the production of each product.

3. Completed quality testing system for the semi-finished products and finised products.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.